PROJECT OVERVIEW

“InstaTurf surprised me”: Standing Strong Against Hurricane Forces

Customer:

Power Company via Ferguson Waterworks

Location:

Eastern Virginia

Product:

APPLICATION:

Protecting a power substation experiencing heavy precipitation and repeated TRM/sod failure.

SITE DESCRIPTION:

- Standard annual/perennial grass and legume mix

- Silty Clay Loam soil

- Approximate 4 ft wide channel bottom

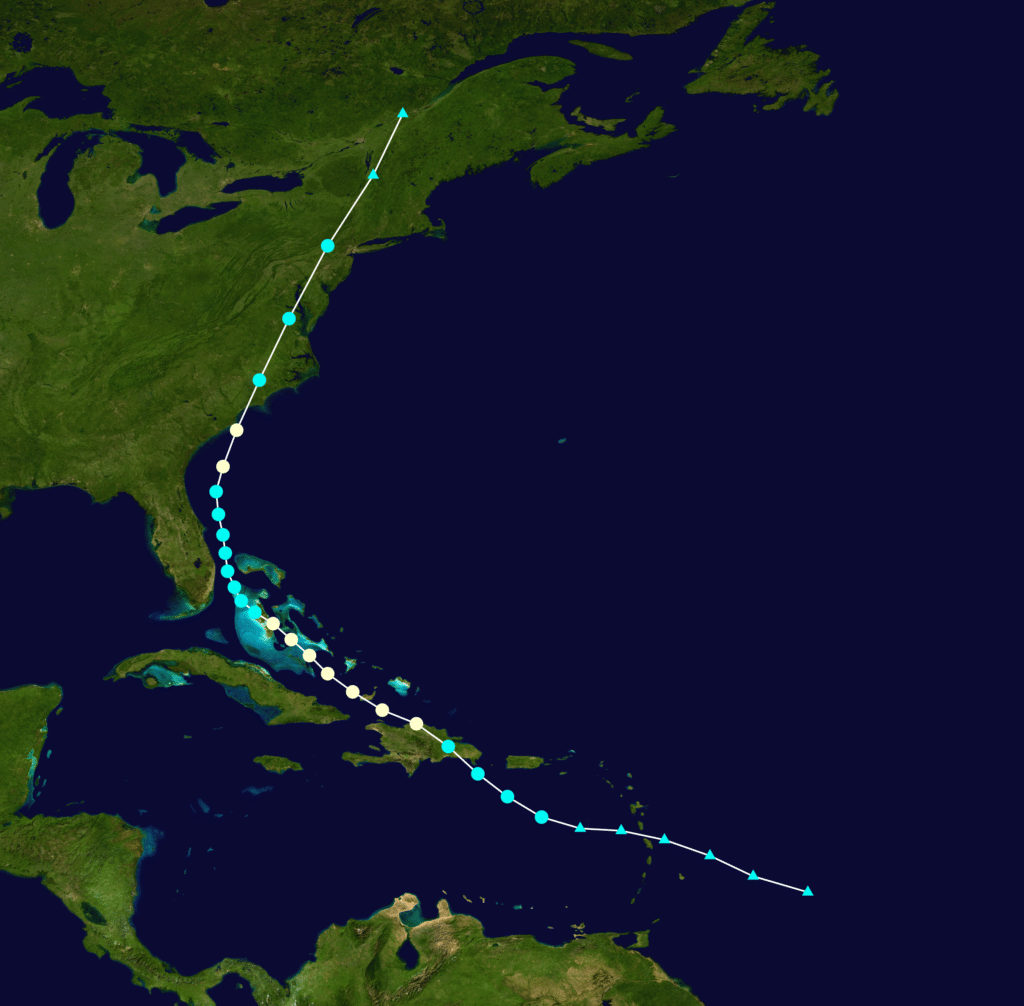

- Experienced over 6 inches of rainfall and 50+ mph winds over several days

Background

Ferguson Waterworks, an InstaTurf ShearForce products distributor, was contacted by the owner of a power substation in Eastern Virginia that was experiencing a recurring erosion problem. After a few storm events, the sod that the property owner was using to protect an outfall area and drainage channel on their site had to be replaced or repaired. The problem was proving costly and apparently insurmountable.

Scour and erosion in the outfall and channel were common sights, and every time the site owners spent resources to fix the problem, a storm would come and ruin their work before root development was adequate to protect the soil and keep the sod in place. Del Fuller, a sales associate with Ferguson Waterworks relished the opportunity to provide a solution to a problem that had cost the site owners time and money—but knew it was going to be a challenge since turf reinforcement mats (TRMs) had been previously installed in the channel before the sod, and those, too, had failed.

In such cases with significant immediate erosion potential, rock riprap is often the “default” solution for permanent erosion protection, and the owner was considering using it on this site as a last resort. In this case, though, rock was a major logistical challenge as 100 truckloads of material would need to be transported to this limited-access site. They needed a solution that would provide immediate erosion protection like rock but was also lightweight and more suitable for a remote location. The typical solutions just weren’t up to snuff.

Solution

Del recommended a new product that Ferguson Waterworks had just begun to represent, the InstaTurf ShearForce10 hybrid-turf Instant Armor Mat. It’s lightweight and immediately effective for preventing erosion under high velocity, high shear stress water flow. Based on the product’s design data, the ShearForce10 appeared to be a viable solution for the outfall and channel on the substation site, but Del had limited actual field experience with the product at that point. He was confident in the product, but spec sheets and laboratory test results don’t always guarantee effective in-field performance.

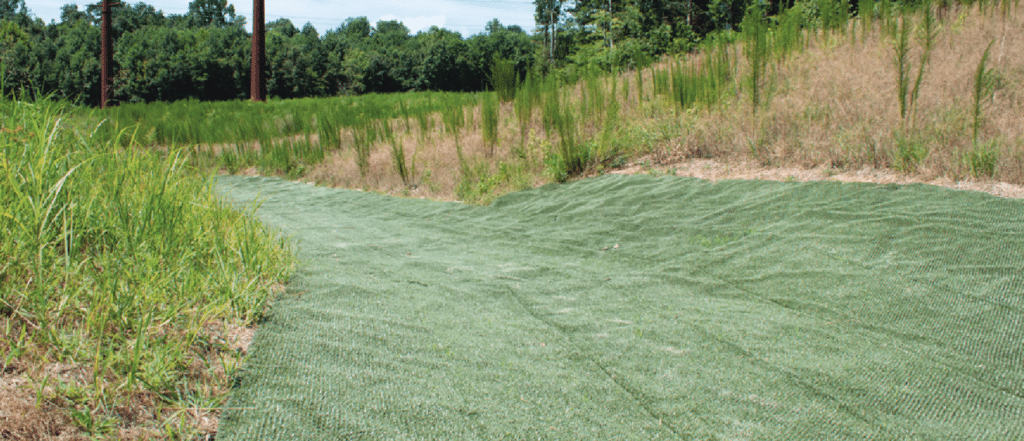

After the substation owner decided to move forward with the ShearForce10 instead of rock and the local county engineer approved their plans, Ferguson Waterworks shipped enough ShearForce10 to cover approximately 13,000 sf to the site. All told, the ShearForce10 product only filled about half a truck, so the remoteness of the site was a non-issue. Since no heavy equipment was necessary for installation, it was also a great deal easier than rock to be put in place. The installation would have been much more difficult and costly if rock had been used. It would’ve been a logistical headache, and the expense to haul the material in would have been prohibitively high, let alone the installation costs. It was all going well, but rough weather would soon put the ShearForce10 to the test.

Not two weeks after installation, Del received concerning news: The remnants of Hurricane Isaias hit the substation, with the freshly installed ShearForce10 taking the full brunt of the 6” of rainfall and 50+ mph winds. Much smaller storms than this had knocked out sod and TRM installations on this site in the past. Dreading an uncomfortable phone call from the site owner, Del couldn’t sit idly by, so he decided to visit the site himself just after the storm cleared.

Results

From the debris and stormwater still draining into the outfall area and downstream through the channel, it was obvious that a major storm had come through—you could expect no less after such a deluge—but then Del saw something hopeful: the water running by was clear. He had faith in the ShearForce10 product, but under the circumstances he hadn’t dared to expect such a positive sign. There was no visible soil loss in the outfall area or channel.

Del visited the site again when the water receded, and his hunch was dead on; there was no need for repairs. InstaTurf was no worse for wear and the telltale signs of soil loss were nowhere to be found. In fact, grass was already coming through the simulated turf structure of the ShearForce10. Roots were developing and further enhancing the already outstanding soil protection this “hybrid-turf” product provided. The ShearForce10 stood strong against the heavy weather. The product’s spec sheets and ASTM test reports were one thing, but now Del had directly witnessed its real-world capabilities, and he was blown away.

This was also a boon for the site owners. Where sod and TRMs had previously failed under less severe storms, and riprap was going to be extremely expensive to install, the ShearForce10 Instant Armor Mat just took on hurricane force flows with no erosion issues. Here was a product that was lightweight, immediately reliable, and easy to maintain. Impressed with such performance, the site owner now uses ShearForce10 on other projects sites as a cost-effective alternative to rock.